Panasonic Holdings held a groundbreaking ceremony for a new pure electric vehicle battery factory in Kinokawa City, Wakayama Prefecture. Panasonic invested about 70 billion yen (about 3.5 billion yuan) to transform the factory to produce components for on-board batteries, which will be supplied to the American electric vehicle giant Tesla. Mass production will begin after the final evaluation of the new battery is completed. The factory will also be responsible for teaching the mass production technology of new batteries to American electric vehicle factories. Also recently, according to Kyodo News, Japan’s Sharp Corporation revealed that it will officially launch a pure electric vehicle business and hopes to make it a “new pillar of income.”

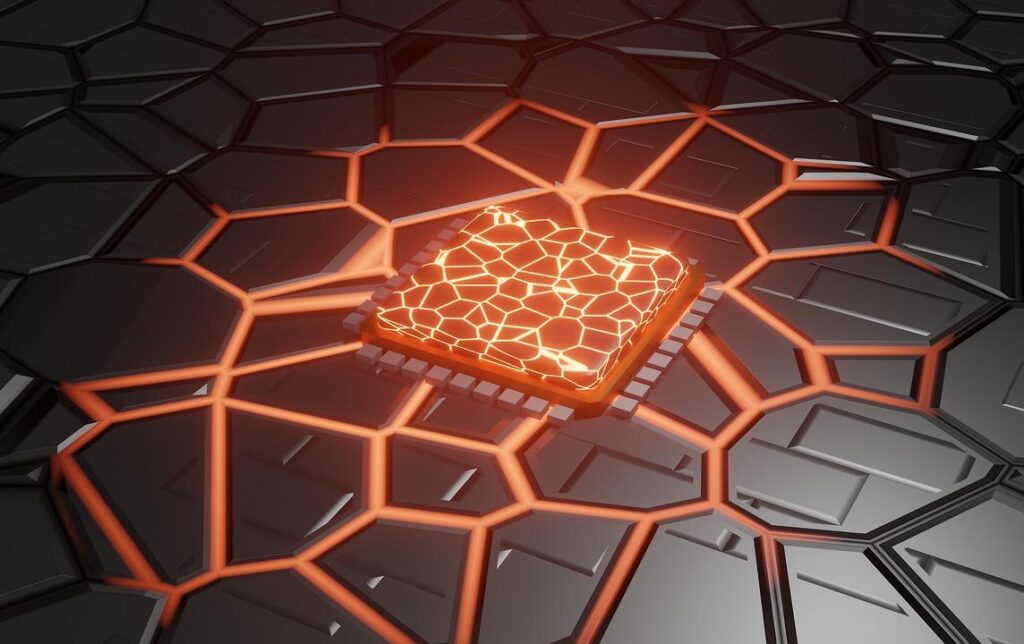

Panasonic’s new battery is cylindrical, the same as ordinary dry batteries, with a diameter of 46 mm and a length of 80 mm, and is called “4680”. Because its capacity is 5 times that of the traditional “2170” model, the number of batteries carried by electric vehicles can be reduced to a few hundred. Taking the battery used in Tesla’s popular model “Model Y” as an example, using 2170 requires connecting about 4,000 cylindrical batteries, while 4680 only requires about 800. Generally, the welding costs of connecting cylindrical batteries are borne by automakers. Fewer welding times means fewer assembly processes and fewer people, which can cut costs and help lower the price of pure electric vehicles. In addition, since there are gaps when the batteries are arranged, it also has superior cooling performance.

Amid increasingly fierce competition between Chinese and Korean companies, Panasonic hopes to differentiate itself through new batteries and seize new market demand.

On the other hand, the current global demand for electric vehicles is slowing, and some automakers have lowered their production plans. Panasonic Energy said: “In the medium and long term, market expansion is an inevitable trend. The results of technological innovation at the Wakayama plant will surely benefit from other plants.”

If the Wakayama plant establishes mass production technology, it will gain an advantage in the competition for orders. Large European automakers are considering adopting 4680, which will help Panasonic catch up with the leading market position of China’s Contemporary Amperex Technology Co., Ltd. (CATL).

As a veteran electronics company, Sharp announced in May this year a structural reform of its “equipment business” including liquid crystals. The Sakai plant, which produces large-size LCD panels for TVs, stopped production in August, and the company needs to come up with a route to profitability as soon as possible. Sharp Chief Technology Officer Mototaka Taneya said on September 6: “The company is discussing entering the pure electric vehicle (EV) business within a few years.” Taneya mentioned that he does not rule out the possibility of cooperating with its parent company, Taiwan Hon Hai Precision Industry, to develop under the Sharp brand.

Sharp’s confidence in entering the electric vehicle market at this time comes from the source. Chen Yan, director of the Japan Enterprise (China) Research Institute, told the Global Times reporter that Sharp currently has a certain accumulation in the fields of electronic control components and batteries. With the continuous development of electric vehicle battery technology, Sharp’s competitiveness will gradually emerge. In addition, Sharp will also receive considerable subsidies from the Japanese government. However, Chen Yan also added that the effect of the parent company Hon Hai Precision Industry’s help to Sharp remains to be seen. Previously, it did not play a big role in helping Sharp’s LCD TV product line.

Since last year, Sharp has started to hold a technology display event “SHARP Tech-Day” with the goal of achieving a more comfortable life in the future. This year’s event focuses on showcasing Sharp’s solutions in the fields of artificial intelligence, green energy, and communications. Sharp’s first electric vehicle concept car will also be unveiled at the event.

The “LDK+” on display this time is a brand-new EV concept car designed based on Foxconn’s EV platform. It was produced with the assistance of EV startup Folofly, and the rear seats will be equipped with LCD screens manufactured by Sharp.

If you want to know more about Japan, please continue to follow this site. We will wholeheartedly provide you with professional consultation and support to help you succeed in the Japanese market.