Chiyoda Corporation’s Breakthrough in Green Chemistry

Japan’s Chiyoda Corporation has successfully commercialized an innovative technology that utilizes carbon dioxide to produce resin raw materials for clothing and automotive parts. This groundbreaking technique aims to replace traditional petroleum-based production methods, significantly reducing carbon dioxide emissions and contributing to the decarbonization of supply chains in the fashion and automotive industries.

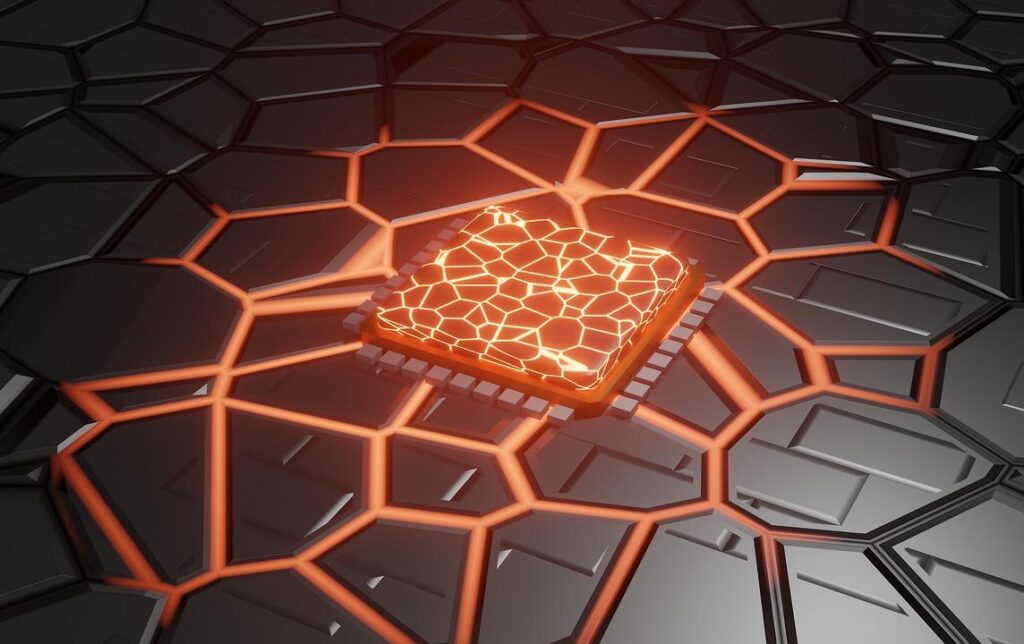

Technical Principles and Innovation

The technology primarily focuses on the production of terephthalic acid, a key ingredient in polyester fibers and PET bottle resins. Traditionally, terephthalic acid is obtained by oxidizing paraxylene, which is mainly extracted from crude oil. Chiyoda’s new method employs a mixture of metal catalysts and zeolite catalysts to react carbon dioxide with hydrogen, directly producing paraxylene, thus eliminating the need for petroleum.

Projected Emission Reduction

According to estimates, this new method can absorb approximately 30,000 tons of carbon dioxide when producing 10,000 tons of paraxylene. In contrast, the conventional petroleum-based production method would emit nearly 10,000 tons of carbon dioxide. Consequently, the application of this new technology has the potential to reduce carbon dioxide emissions by about 40,000 tons for every 10,000 tons of paraxylene produced.

Research Progress and Future Plans

Chiyoda Corporation has been collaborating with institutions such as the University of Toyama to advance this technology. The company plans to begin construction of large-scale verification facilities as early as 2026, aiming for commercial operation in the 2030s. If successful, this will mark the world’s first practical application of paraxylene production from carbon dioxide.

Potential Impact

The successful application of this technology could have far-reaching implications for the chemical industry. It not only reduces dependence on petroleum but also significantly lowers carbon emissions in the production of resin raw materials. This is particularly significant for supply chain decarbonization in industries such as fashion and automotive, promoting a more sustainable development trajectory for these sectors.

Conclusion

Chiyoda Corporation’s innovative technology represents a significant step towards green transformation in the chemical industry. By utilizing carbon dioxide instead of petroleum to produce resin raw materials, it achieves both resource recycling and provides a new solution for reducing greenhouse gas emissions. As the technology further develops and commercializes, it has the potential to make a positive contribution to addressing global climate change issues.

If you plan to expand into the Japanese market or want to learn more about it, please contact our professional consultant Jaycy. We will provide you with detailed market analysis, investment advice, and a full range of overseas expansion support services. Click the consultation icon on the right side of the website to communicate with us and start your journey into the Japanese market.