Japanese manufacturing has long played a pivotal role on the global economic stage. Since the economic recovery period after World War II, Japan has established the golden signboard of “Made in Japan” in the fields of automobiles, electronics, machinery, etc. with its exquisite craftsmanship, rigorous management and unremitting innovation. This lofty reputation has not only promoted the rapid development of Japan’s economy, but also set a benchmark for the global manufacturing industry. Today, despite facing fierce competition from emerging economies, Japan’s manufacturing industry is still an important pillar supporting the national economy, and maintains a world-leading position in high-end manufacturing, precision instruments and cutting-edge technology research and development.

However, with the rapid changes in the global economic landscape, the accelerated advancement of technological innovation, and the significant changes in Japan’s domestic population structure, Japan’s manufacturing industry is facing unprecedented challenges and opportunities. This report aims to deeply analyze the current situation of Japan’s manufacturing industry, predict major trends that may emerge in the next five years, and focus on the potential opportunities and challenges that these changes bring to Chinese companies. Through comprehensive data analysis, expert interviews and case studies, we strive to provide insights and guidance for Chinese companies that are interested in developing the Japanese market, and at the same time paint a promising blueprint for the cooperative development of the manufacturing industries of the two countries.

This study uses a variety of research methods, including but not limited to: in-depth literature review, industry data analysis, in-depth interviews with experts, field visits and case studies. We have collected the latest data and opinions from Japanese government departments, industry associations, leading companies and research institutions, and have also widely absorbed relevant research results from international organizations and multinational companies. Through this multi-dimensional and multi-angle research method, we strive to present a comprehensive, objective and forward-looking industry report to provide readers with deep insights into the future development of Japan’s manufacturing industry.

Current status of Japanese manufacturing industry

The industrial distribution of Japan’s manufacturing industry is characterized by diversification and high specialization. As a pillar industry in Japan, the automobile manufacturing industry, represented by world-renowned brands such as Toyota, Honda, and Nissan, occupies an important position in the global market. In 2023, the output value of Japan’s automobile industry will reach about 47 trillion yen, accounting for about 18% of the total output value of the manufacturing industry.

The electronics and electrical industry is another important field. Companies such as Sony, Panasonic, and Hitachi maintain strong competitiveness in consumer electronics and industrial electronic equipment, with an annual output value of about 16 trillion yen. In the machinery manufacturing industry, especially in the fields of precision machine tools and industrial robots, Japanese companies such as Fanuc and Yaskawa Electric continue to lead global technological development, with an annual output value of about 15 trillion yen. In addition, the chemical industry, steel manufacturing, medical equipment and other fields are also important parts of Japan’s manufacturing industry, together forming a comprehensive and powerful industrial ecosystem.

In recent years, the development of Japan’s manufacturing industry has shown a complex situation. On the one hand, Japanese companies continue to maintain significant advantages in high-end manufacturing and innovative technologies. For example, in the fields of semiconductor manufacturing equipment, new material development, hydrogen energy technology, etc., Japanese companies are still in a leading position in the world. In 2022, Japan’s manufacturing R&D investment accounted for 3.5% of GDP, much higher than most developed countries. On the other hand, Japan’s manufacturing industry is also facing severe challenges. The primary problem is the labor shortage caused by an aging population, which not only pushes up production costs, but also affects technology inheritance and innovation. Data show that in 2023, the average age of Japanese manufacturing employees has exceeded 45 years old, and is showing an upward trend year by year.

In addition, the rise of emerging economies in the process of globalization has also brought tremendous pressure to Japan’s manufacturing industry. Especially in the field of mid- and low-end manufacturing, Japanese companies face fierce competition from countries such as China and South Korea. In response to this challenge, many Japanese companies have begun to transfer their production bases overseas, resulting in the increasingly serious problem of domestic industrial hollowing out. According to statistics, Japan’s overseas production ratio has exceeded 35% in 2022, an increase of nearly 10 percentage points from ten years ago.

In the face of these challenges, the Japanese government and companies are taking active measures. The implementation of the “Society 5.0” strategy aims to improve production efficiency by promoting digital transformation and the application of artificial intelligence. At the same time, Japan is also increasing investment in emerging technology fields such as hydrogen energy, biotechnology and nanomaterials, in order to gain a favorable position in the new round of industrial revolution. However, how to effectively respond to demographic changes and global competitive pressures while maintaining technological leadership remains a long-term challenge facing Japan’s manufacturing industry.

Key factors affecting the future development of Japan’s manufacturing industry

Population aging and labor shortages are among the most severe challenges facing Japan’s manufacturing industry. According to the National Institute of Population and Social Security Research, by 2030, the proportion of people aged 65 and above in Japan will reach 31.2%. This demographic change has directly led to a reduction in labor supply and a worsening talent gap in the manufacturing industry. A 2023 survey showed that more than 70% of Japanese manufacturing companies said they were facing difficulties in recruiting workers.

To address this problem, Japanese companies are increasing their investment in automation and robotics, while also actively exploring flexible employment systems and delayed retirement policies. However, how to maintain technological inheritance and innovation while ensuring production efficiency remains a difficult problem that needs to be solved.

Technological innovation and digital transformation are the core driving forces for the future development of Japan’s manufacturing industry. Emerging technologies such as Industry 4.0, Internet of Things (IoT), artificial intelligence (AI) and big data analysis are profoundly changing the production model and value chain of the manufacturing industry. According to data from the Ministry of Economy, Trade and Industry of Japan, Japan’s investment in digitalization of the manufacturing industry will increase by 15% year-on-year to 2.8 trillion yen in 2023.

Leading companies such as FANUC and Panasonic are actively promoting the construction of “smart factories” and optimizing production processes through digital twin technology to improve efficiency and flexibility. However, small and medium-sized enterprises still face challenges such as funding and talent shortages in digital transformation. How to promote the balanced development of the entire industrial chain is a key issue that the Japanese manufacturing industry needs to solve.

Changes in the global economic landscape have had a profound impact on Japan’s manufacturing industry. The rapid rise of emerging markets such as China and India has brought new market opportunities and intensified competitive pressure. At the same time, global trade frictions and supply chain reshaping have also brought challenges to Japanese companies. A survey in 2022 showed that more than 60% of Japanese manufacturing companies are considering adjusting their global supply chain strategies. In this context, how to balance internationalization and localization, global layout and risk control has become a strategic issue facing Japan’s manufacturing industry.

The pressure of environmental protection and sustainable development is increasing. The Japanese government has pledged to achieve carbon neutrality by 2050, which has put forward higher environmental protection requirements for the manufacturing industry. Data shows that Japan’s manufacturing industry’s carbon dioxide emissions in 2023 will be reduced by about 20% compared with 2013, but there is still a large gap from the target of 46% reduction in emissions by 2030. To this end, Japanese companies are increasing their investment in clean energy, energy-saving technologies and circular economy models. Toyota, Hitachi and other companies have announced the goal of achieving carbon neutrality by 2040, leading the green transformation of the industry. However, how to meet increasingly stringent environmental standards while maintaining competitiveness remains a major challenge facing the manufacturing industry.

Government policy support plays a key role in promoting the transformation and upgrading of Japan’s manufacturing industry. A series of policies such as the “Society 5.0” strategy and the “Digital Japan” plan aim to enhance the competitiveness of the manufacturing industry through technological innovation and digital transformation. In 2023, the Japanese government established a 1 trillion yen “Economic Security Guarantee” fund to support the research and development and industrialization of key areas such as semiconductors and artificial intelligence. At the same time, tax incentives, subsidies and other measures are used to encourage companies to increase R&D investment and equipment upgrades. However, how to balance market mechanisms and government intervention to ensure the maximization of policy effects still requires close collaboration and continuous adjustments between the government and enterprises.

Forecast of Japanese manufacturing industry development trends in the next five years

The comprehensive promotion of smart manufacturing and Industry 4.0 will become the core development trend of Japan’s manufacturing industry in the next five years. The Ministry of Economy, Trade and Industry of Japan predicts that by 2028, the scale of Japan’s smart manufacturing market will reach 3.5 trillion yen, with an average annual growth rate of about 15%. Large manufacturing companies such as Toyota and Hitachi have begun to deploy industrial Internet of Things (IIoT) and artificial intelligence (AI) systems on a large scale to achieve real-time monitoring, predictive maintenance and autonomous decision-making of production processes. For example, FANUC is promoting its “zero downtime” factory model, which predicts equipment failures through AI algorithms and increases production efficiency by 30%. In the future, we will see more small and medium-sized enterprises join the wave of smart manufacturing and promote the digital transformation of the entire manufacturing ecosystem.

The improvement of robotics and automation will significantly change the production model of Japan’s manufacturing industry. Faced with the pressure of labor shortage, Japanese companies are accelerating the adoption of advanced robots and automation systems. The Japan Robot Industry Association predicts that by 2027, the annual installation of industrial robots in Japan will exceed 300,000 units, a 40% increase from 2022. New robots such as collaborative robots and autonomous mobile robots (AMR) will be widely used in manufacturing workshops. Leading companies such as Yaskawa Electric are developing a new generation of robots with high flexibility and learning ability that can adapt to changing production needs. This trend will not only improve production efficiency, but also reshape the factory labor structure and promote the growth of demand for high-skilled workers.

The application of new materials and green manufacturing technologies will become an important direction for innovation in Japan’s manufacturing industry. In order to achieve the goal of carbon neutrality in 2050, Japanese companies are actively developing and applying environmentally friendly materials and clean production technologies. According to the New Energy and Industrial Technology Development Organization (NEDO) of Japan, the market size of Japan’s green manufacturing technology will reach 2 trillion yen by 2026. Lightweight and environmentally friendly materials such as carbon fiber composites and bio-based plastics will be more widely used in industries such as automobiles and electronics. At the same time, clean energy technologies such as hydrogen energy utilization and industrial waste heat recovery will also play a greater role in the manufacturing process. Material giants such as Toray and Mitsubishi Chemical are increasing their investment in the research and development of a new generation of environmentally friendly materials, and are expected to launch revolutionary products in the next few years.

Industrial chain reconstruction and globalization strategy adjustment will become key measures for Japan’s manufacturing industry to cope with changes in the international situation. Affected by global trade frictions and the COVID-19 pandemic, Japanese companies are reassessing their global supply chain strategies. According to a survey by the Japan External Trade Organization (JETRO), more than 40% of Japanese manufacturing companies plan to adjust their overseas production layout in the next three years. The “China + 1” strategy will continue to be implemented, and the trend of diversification of production bases focusing on Southeast Asian countries will become more obvious. At the same time, in order to ensure the supply security of key technologies and core components, some high-value-added production links are expected to return to Japan. This trend will promote the reorganization and upgrading of domestic industrial clusters in Japan, especially in strategic areas such as semiconductors and new energy batteries.

The transformation of manufacturing industry into service industry will accelerate in the next five years and become an important means for Japanese manufacturing enterprises to enhance their competitiveness. As the competition of product homogeneity intensifies, more and more Japanese manufacturing enterprises are beginning to transform into comprehensive solution providers of “manufacturing + service”. Mitsubishi Electric, JTEKT and other enterprises are strengthening their software development and data analysis capabilities to provide customers with value-added services such as equipment maintenance and energy management. According to the Japan Information Technology Service Industry Association, by 2027, the scale of Japan’s industrial service market will reach 10 trillion yen, with an average annual growth rate of more than 10%. This transformation will not only increase the profit margins of manufacturing enterprises, but also deepen their cooperation with customers and enhance their market competitiveness.

Analysis on the development prospects of key industries

As the pillar of Japan’s manufacturing industry, the automobile industry is undergoing profound changes in electrification, intelligence and networking. The Japan Automobile Industry Association predicts that by 2028, Japan’s annual production of electric vehicles (including pure electric, plug-in hybrid and fuel cell vehicles) will reach 3 million, accounting for more than 50% of the total production. Toyota, Honda and other giants are increasing their investment in solid-state batteries and autonomous driving technologies, and are expected to launch mass-produced models equipped with L3 autonomous driving systems after 2025. At the same time, the rise of the concept of software-defined vehicles (SDV) has promoted the deep integration of the automotive industry and the IT industry. Companies such as Nissan and Mazda are working with technology companies to develop a new generation of in-vehicle operating systems and cloud service platforms. This trend will reshape the automotive industry chain and promote the transformation of traditional parts suppliers into system integrators.

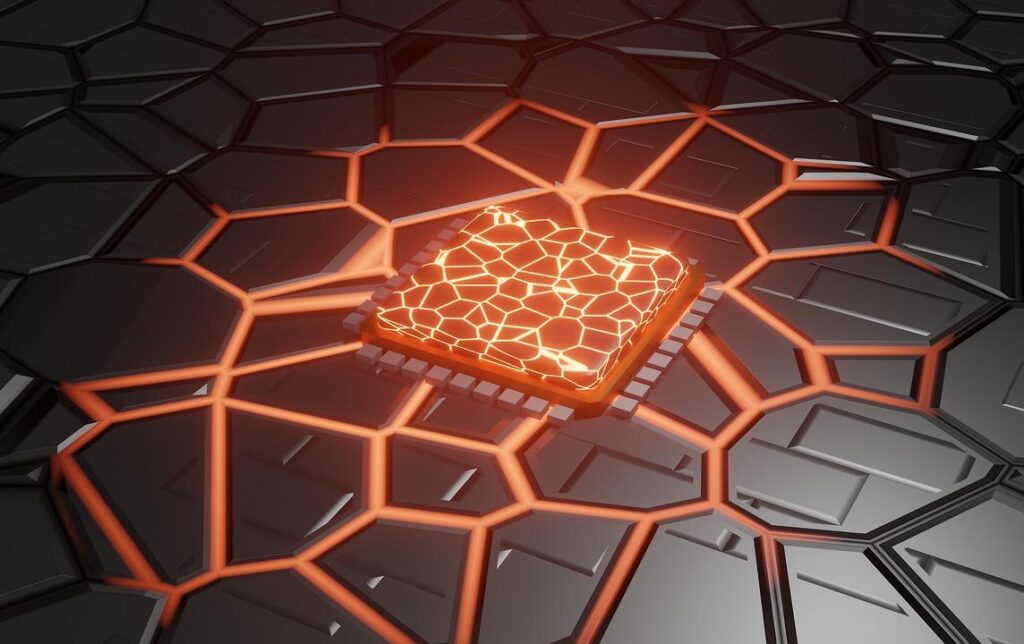

The development focus of the electronics and electrical industry will be on semiconductors and new display technologies. The Ministry of Economy, Trade and Industry of Japan predicts that by 2026, the scale of Japan’s semiconductor industry will exceed 5 trillion yen. The global leading position of companies such as Tokyo Electron and Adaman in the field of semiconductor manufacturing equipment and materials will be further consolidated. At the same time, Japanese companies are actively planning the research and development and industrialization of third-generation semiconductors (such as silicon carbide and gallium nitride), and are expected to take the lead in emerging application fields such as new energy vehicles and 5G communications. In terms of display technology, companies such as Sharp and JDI are promoting the mass production of new display technologies such as OLED and Micro LED, and are expected to perform well in the high-end consumer electronics and automotive display markets.

The machinery manufacturing industry, especially in the field of precision machine tools and industrial robots, will continue to maintain its global competitive advantage. The Japan Machine Tool Industry Association predicts that by 2027, Japan’s precision machine tool exports will reach 1.5 trillion yen, with an average annual growth of about 5%. Leading companies such as Mazak and Mori Seiki are accelerating the research and development and promotion of high-end CNC machine tools such as 5-axis linkage and additive manufacturing to meet the high-precision processing needs of aerospace, medical equipment, etc. In terms of industrial robots, companies such as FANUC and Yaskawa Electric are actively developing a new generation of collaborative robots and flexible manufacturing systems. It is expected that by 2026, Japan’s annual output of industrial robots will exceed 350,000 units, and its global market share will remain above 40%.

The medical equipment industry, especially high-end medical devices and biotechnology, will become a new growth point for Japan’s manufacturing industry. The Japan Medical Device Industry Association predicts that by 2028, the size of Japan’s medical device market will reach 4.5 trillion yen, with an average annual growth rate of about 6%. The positions of companies such as Olympus and Shimadzu Corporation in traditional advantageous fields such as endoscopes and imaging diagnostic equipment will be further consolidated. At the same time, companies such as Fujifilm and Terumo are increasing their investment in cutting-edge technologies such as regenerative medicine and gene therapy, and are expected to make breakthroughs in emerging markets such as personalized medicine and chronic disease management. Digital medical solutions such as artificial intelligence-assisted diagnosis and telemedicine will also become the focus of Japanese medical device companies.

The new energy industry, especially hydrogen energy and energy storage technology, will play a key role in Japan’s “carbon neutrality” strategy. The Japan Hydrogen Energy Association predicts that by 2030, the scale of Japan’s hydrogen energy-related industries will reach 1 trillion yen. Companies such as Toyota and Kawasaki Heavy Industries are accelerating the commercialization of hydrogen fuel cell vehicles, hydrogen power plants and other application scenarios. In terms of energy storage technology, battery manufacturers such as Panasonic and GS Yuasa are actively developing new-generation battery technologies such as all-solid-state batteries and sodium-ion batteries. It is expected that by 2027, Japan’s power battery production capacity will reach 100GWh, and it is expected to occupy a favorable position in the fields of electric vehicles and renewable energy grid connection. At the same time, Japanese companies are also actively exploring the integrated application of hydrogen energy and renewable energy, such as photovoltaic hydrogen production and wind power hydrogen production, to provide a full range of solutions for building a clean energy system.

Opportunities for Chinese companies

Technological cooperation and innovation sharing provide an important way for Chinese companies to enter the high-end field of Japanese manufacturing. In recent years, facing the pressure of talent shortage and rising R&D costs, Japanese companies have become more and more open to cooperation and innovation. According to statistics from the Japan-China Economic Association, the number of joint R&D projects between China and Japan in the fields of artificial intelligence, new materials, etc. will increase by 30% year-on-year in 2023. For example, the cross-licensing of patents between Huawei and Sony in the field of 5G technology and the strategic cooperation between Alibaba and Panasonic in the Internet of Things platform reflect this trend. In the next five years, in cutting-edge fields such as semiconductors, robots, and new energy vehicles, Chinese companies are expected to accelerate the improvement of their own innovation capabilities through technological cooperation, while bringing new development momentum to Japanese partners.

The market space in the field of high-end manufacturing provides new growth opportunities for Chinese companies. As Japan’s manufacturing industry transforms to higher value-added areas, new opportunities have emerged in some mid-to-high-end markets. According to data from the Japan External Trade Organization (JETRO), China’s exports of high-tech products to Japan will increase by 15% year-on-year to 200 billion yuan in 2023. Especially in the fields of industrial robots, new energy equipment, high-end medical devices, etc., the cost-effectiveness of Chinese companies is gradually being recognized by the Japanese market. For example, DJI’s industrial-grade drones continue to grow in share in Japan’s agricultural and mapping markets, and CATL’s power battery products have also begun to enter Japan’s electric vehicle supply chain. In the future, with the continuous upgrading of China’s manufacturing industry, Chinese companies are expected to appear in more high-end market segments.

The complementary and coordinated development of the industrial chain has created win-win opportunities for Chinese and Japanese companies. Japan’s advantages in high-end components and key materials complement China’s advantages in manufacturing scale and market size. According to statistics from the Ministry of Commerce of China, the industrial chain cooperation projects between China and Japan in the fields of electronic information, auto parts, etc. increased by 20% in 2023. For example, the cooperation between BYD and Nidec in electric vehicle motor systems and the strategic alliance between Haier and Mitsubishi Electric in the field of smart home appliances reflect this complementary advantage. In the future, with the in-depth implementation of the Regional Comprehensive Economic Partnership Agreement (RCEP), the coordination between China and Japan at the industrial chain and supply chain level will be further strengthened, opening up a broader space for cooperation for enterprises on both sides.

The exchange of digital transformation experience provides Chinese companies with valuable learning opportunities. Japan has accumulated rich experience in promoting Industry 4.0 and intelligent manufacturing, especially in production process optimization and quality control. According to a report from the China Academy of Information and Communications Technology, more than 100 Chinese manufacturing companies will visit Japan to learn about digital transformation experience in 2023. For example, Haier Group has successfully built its own intelligent manufacturing system by learning from Toyota’s production method and Hitachi’s IoT platform. In the future, as China’s manufacturing industry deepens its digital transformation, exchanges of experience with Japanese companies in industrial software, data analysis, artificial intelligence applications, etc. will become more frequent, which will help Chinese companies accelerate their digital upgrades.

Green manufacturing technology cooperation has become a new highlight of cooperation between Chinese and Japanese companies. With the two governments attaching importance to environmental protection and sustainable development, there is great potential for cooperation in the field of green manufacturing. According to data from the Ministry of Ecology and Environment of China, the number of technology transfer and cooperation projects between China and Japan in the fields of clean energy, energy conservation and environmental protection increased by 40% year-on-year in 2023. For example, the cooperation between China Baowu and Nippon Steel & Sumitomo Metal in hydrogen steelmaking technology, and the strategic partnership between Envision Energy and Marubeni Corporation in the field of offshore wind power, both represent this trend. In the next five years, with the advancement of the carbon neutrality goal, Chinese and Japanese companies are expected to carry out deeper technical cooperation in the fields of new energy vehicles, renewable energy equipment, environmentally friendly materials, etc., and jointly promote the innovation and application of green manufacturing technology.

Challenges facing Chinese companies

Technological barriers and intellectual property protection are the primary challenges facing Chinese companies entering the Japanese manufacturing market. Japan’s long-term accumulated technological advantages in the field of high-end manufacturing have formed a high entry barrier. According to data from the Japan Patent Office, the number of patent applications by Japanese companies in manufacturing-related fields in 2023 will still be three times that of Chinese companies. For example, in the fields of semiconductors and precision instruments, Japanese companies have a large number of core patents and proprietary technologies. At the same time, Japan’s strict intellectual property protection system also puts pressure on Chinese companies. In 2023, more than 20 intellectual property lawsuits involving Chinese companies were heard in Japanese courts. Therefore, Chinese companies need to invest more resources in technological innovation and intellectual property management and establish a sound intellectual property strategy to meet this challenge.

Cultural differences and conflicts in management concepts are common problems encountered by Chinese companies when doing business in Japan. Japan’s corporate culture emphasizes collectivism, lifetime employment and incremental innovation, which is in sharp contrast to the rapid decision-making, high employee turnover and disruptive innovation common in Chinese companies. A survey by the Ministry of Economy, Trade and Industry of Japan showed that 45% of Sino-Japanese joint ventures in 2023 said that management efficiency was inefficient due to cultural differences. For example, when Huawei acquired Japanese companies, it faced employee resistance due to differences in management methods. In addition, Japan’s unique decision-making culture such as “nekaishi” (prior communication) and “borenxiang” (reporting, contacting, and discussing) often confuses Chinese managers. To overcome these cultural barriers, Chinese companies need to invest a lot of time and energy to understand and adapt to Japan’s business culture and cultivate management talents with cross-cultural communication skills.

Market access and regulatory policy adaptation are another major challenge facing Chinese companies in expanding their business in Japan. In recent years, the Japanese government has strengthened its review of foreign investment, especially in areas involving national security and key technologies. The Foreign Exchange Law, revised in 2023, further tightened the regulations on foreign investment in Japanese high-tech companies. Data shows that the number of mergers and acquisitions by Chinese companies in Japan fell by 30% year-on-year in 2023. In addition, Japan’s complex product certification system and strict quality standards also pose challenges to Chinese companies. For example, in the field of medical devices, it often takes 2-3 years to obtain certification from the Japanese Medical Device Regulatory Authority (PMDA), which is much longer than other markets. Therefore, Chinese companies need to have a deep understanding of Japan’s laws, regulations and industry standards, formulate long-term market entry strategies, and do a good job of compliance management.

Localized operations and talent cultivation are key challenges for Chinese companies to achieve sustainable development in Japan. The high requirements of the Japanese market for product quality and service levels, as well as consumers’ preference for local brands, make it difficult for simple “OEM production” or “OEM model” to succeed. According to a survey by the Japan External Trade Organization (JETRO), 90% of Chinese companies that succeeded in the Japanese market in 2023 adopted a deep localization strategy. However, the biggest obstacle in the localization process is the shortage of talent. According to statistics, in 2023, there was a shortage of more than 5,000 senior management talents with Japanese business skills and understanding of the Japanese market in Chinese companies in Japan. For example, Xiaomi’s expansion in the Japanese market was slow due to a lack of localized talent. Therefore, Chinese companies need to increase their efforts in recruiting and training talents in Japan and establish a localized management team and marketing network.

Geopolitical factors have brought uncertainty to the development of Chinese companies in Japan. In recent years, changes in the global geopolitical situation have had a certain impact on Sino-Japanese economic and trade relations. In 2023, the Japanese government will elevate economic security to a new strategic level and strengthen the control of key technologies and strategic materials. This has led to more scrutiny of Chinese companies’ investments and mergers and acquisitions in some sensitive areas. According to data from the Japanese Cabinet Office, 15% of Sino-Japanese cooperation projects failed to be implemented as scheduled in 2023 due to security reviews. For example, Huawei encountered policy restrictions in the construction of Japan’s 5G network. In addition, the Japanese media’s tendency to report on Chinese companies will also affect the attitudes of the public and customers. Therefore, Chinese companies need to pay close attention to changes in the international situation, improve their political risk management capabilities, and at the same time, reduce the negative impact of geopolitical factors by strengthening corporate social responsibility and enhancing their brand image.

Strategic recommendations for Chinese companies to expand their manufacturing business in Japan

A deep understanding of the Japanese market and regulatory environment is the basis for Chinese companies to successfully enter the Japanese manufacturing industry. The Japanese market has unique consumer habits and business culture, and the regulatory environment is also relatively complex. It is recommended that Chinese companies invest sufficient time and resources in market research before entering the Japanese market. You can consider hiring a local consulting company or establishing a dedicated market research team. For example, before acquiring Toshiba’s home appliance business, Midea Group spent nearly two years conducting in-depth research on the Japanese home appliance market. In addition, companies should also pay close attention to the industrial policies and regulatory trends of the Japanese government. In 2023, Japan revised the Foreign Exchange Law and the Economic Security Promotion Law, which had a significant impact on foreign investment access. Therefore, establishing a sound legal advisory team, regularly participating in industry association activities, and maintaining good communication with government departments are all important means to effectively grasp the policy direction.

Focusing on technological research and development and improving innovation capabilities is the key for Chinese companies to gain a foothold in Japan’s manufacturing industry. Japan is a global leader in many manufacturing fields and has extremely high requirements for technological innovation. It is recommended that Chinese companies increase their R&D investment and consider setting up R&D centers in Japan to attract local high-end talents. For example, Huawei’s R&D center in Yokohama has successfully developed a number of 5G technologies suitable for the Japanese market. At the same time, actively seeking technical cooperation with Japanese companies is also an effective way to quickly improve innovation capabilities. In 2023, BYD and Toyota’s cooperation on electric vehicle battery technology is a successful case. In addition, participating in industry-university-research cooperation projects supported by the Japanese government is also an important channel for obtaining cutting-edge technology and R&D resources. It is recommended that companies pay close attention to relevant project information released by the Ministry of Education, Culture, Sports, Science and Technology and the Ministry of Economy, Trade and Industry of Japan.

Promoting localization strategy and cultivating cross-cultural talents are the inevitable choices for Chinese companies to achieve long-term development in Japan. Japanese consumers have a strong preference for local brands, so deep localization is crucial to brand building. It is recommended that companies fully consider the characteristics of the Japanese market in terms of product design, marketing strategy, and after-sales service. For example, when Xiaomi entered the Japanese market, it specially designed product packaging and user interfaces that conform to Japanese aesthetics. In terms of talent strategy, cultivating compound talents who understand both Chinese corporate culture and the Japanese market is the key. This can be achieved through various means such as sending Chinese employees to Japan for further studies, recruiting Japanese students, and establishing talent training cooperation with Japanese universities. Alibaba’s success in Japan is largely due to its cultivation of an excellent localization team.

Seeking strategic partners and achieving complementary advantages is an effective way for Chinese companies to quickly integrate into the Japanese manufacturing ecosystem. Japan’s manufacturing industry has a complete industrial chain and a mature business network. Establishing strategic partnerships with local companies can help Chinese companies quickly obtain market resources and channel advantages. It is recommended that companies choose appropriate cooperation models based on their own characteristics, such as technology licensing, joint ventures, strategic alliances, etc. In 2023, the joint venture between CATL and Honda in the field of power batteries is a typical case. In addition, actively participating in Japan’s industrial clusters and innovation ecosystems is also an effective way to find potential partners. For example, actively participating in innovation centers and industrial park activities across Japan, such as Tsukuba Research Academy City and Kanagawa Innovation Center, can help companies quickly integrate into local innovation networks.

Focusing on sustainable development and establishing a brand image are important strategies for Chinese companies to win trust in the Japanese market. Japanese society attaches great importance to corporate social responsibility and environmental protection. It is recommended that Chinese companies integrate the concept of sustainable development into their corporate strategies and fully consider environmental factors in product design, manufacturing, supply chain management and other links. For example, Envision Energy’s wind power project in Japan has won the support of the local community for its protection measures for marine ecology. At the same time, actively participating in social welfare activities and cooperating with local non-profit organizations are also effective ways to enhance brand image. Huawei’s “Seeds for the Future” program launched in Japan has effectively improved brand awareness by supporting the cultivation of local ICT talents. In addition, timely and transparent disclosure of corporate social responsibility reports and proactive communication with the media and the public are also key measures to shape a responsible corporate image.

Japan’s manufacturing industry is facing a critical period of transformation and upgrading, with both opportunities and challenges. On the one hand, the application of new technologies such as digital transformation, Industry 4.0 and artificial intelligence has injected new vitality into Japan’s manufacturing industry, which is expected to improve production efficiency and create new business models. The Ministry of Economy, Trade and Industry of Japan predicts that by 2030, smart manufacturing will bring about 30 trillion yen in economic benefits to Japan’s manufacturing industry. On the other hand, problems such as an aging population, labor shortages and intensified global competition have brought tremendous pressure to Japan’s manufacturing industry.

According to data from Japan’s Ministry of Internal Affairs and Communications, the number of people employed in the manufacturing industry in 2023 will be about 40% less than the peak in 1990. Faced with these challenges, Japan’s manufacturing industry is actively promoting structural adjustments, increasing R&D investment, and reshaping the global supply chain. For example, Toyota is accelerating its transformation into a mobile service provider, and Sony is also actively deploying emerging fields such as the metaverse. This transformation is not only related to the future of Japan’s economy, but will also reshape the global manufacturing landscape.

The prospects for the development of Sino-Japanese manufacturing cooperation are broad, but it requires joint efforts from both sides to overcome obstacles and achieve mutual benefit and win-win results. In the fields of technological innovation, industrial upgrading, green manufacturing, etc., China and Japan have broad space for cooperation. The Japan-China Economic Association predicts that by 2025, the bilateral trade volume between China and Japan in the manufacturing sector is expected to exceed US$200 billion. Especially in emerging industries such as electric vehicles, robots, and new materials, the complementary advantages of enterprises in the two countries are becoming increasingly apparent. For example, the competitive and cooperative relationship between CATL and Panasonic in the field of power batteries is driving the rapid development of the global new energy vehicle industry. However, geopolitical factors, cultural differences, market access and other issues are still important factors restricting the in-depth cooperation between the two countries.

In the future, the two governments need to establish a more open and transparent dialogue mechanism to create a good environment for business cooperation. At the same time, enterprises should also improve their cross-cultural management capabilities, strengthen technological innovation and localized operations, and jointly respond to the challenges of globalization. With the in-depth implementation of the Regional Comprehensive Economic Partnership (RCEP), China and Japan, as the two largest economies in Asia, are expected to play a greater role in building a new global value chain and promote the high-quality development of the manufacturing industry in the Asia-Pacific region and even the world.

Looking ahead, the transformation of Japan’s manufacturing industry is full of challenges, but it also contains huge opportunities. By embracing the digital revolution, promoting industrial structure optimization, and deepening international cooperation, Japan is expected to reshape its leading position in the global manufacturing industry. For Chinese companies, deeply participating in the transformation and upgrading process of Japan’s manufacturing industry is not only an important opportunity to expand overseas markets, but also a valuable opportunity to improve their own innovation capabilities and management levels.

As the cooperation between the two countries in high-end manufacturing, green technology, intelligent manufacturing and other fields continues to deepen, China and Japan are expected to jointly lead a new round of changes in the global manufacturing industry and contribute wisdom and strength to global challenges such as addressing climate change and promoting sustainable development. In this process, the foresight of entrepreneurs, the policy support of the government, and the mutual understanding and trust of the people of the two countries will play a key role. Through joint efforts, China and Japan will not only be able to achieve innovative development in their respective manufacturing industries, but also make important contributions to building a more inclusive and sustainable global economic order.